Railcar Facility – North Augusta, SC

We’re going to need a tougher slab.

In North Augusta, South Carolina, thousands of tons of railroad cars and steel components are shipped to and from a major rail maintenance facility every week, wreaking havoc on the hardstand concrete slabs that cover the yard. The punishment from rolling loads, impact loads and abrasive wear is so extreme that the facility has maintained a quarterly rip-and-replace program to deal with the persistent failure of their slabs for more than 20 years.

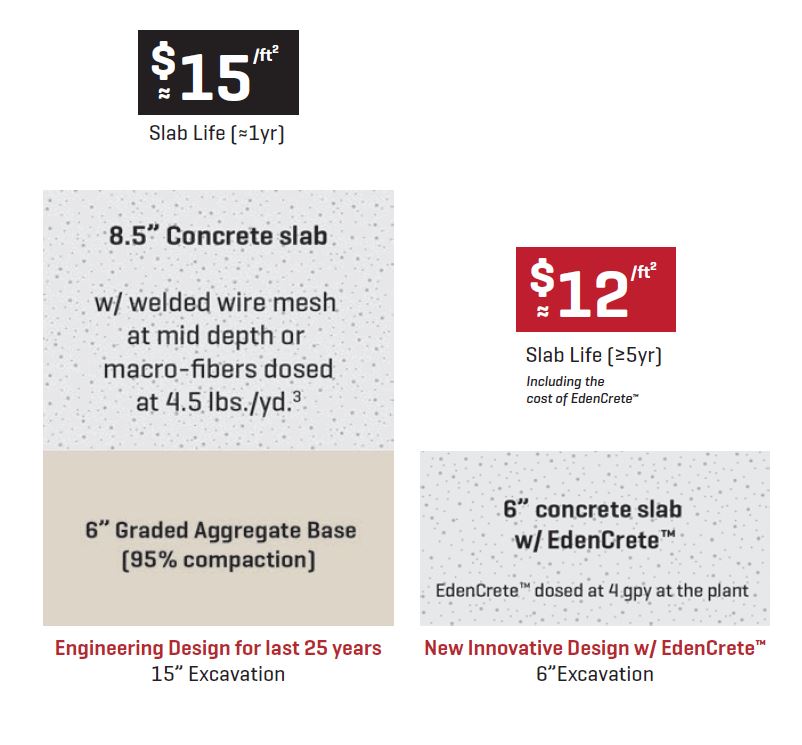

Proposed ultra-high strength design

In an effort to extend the service life of the concrete and reduce replacement projects, an alternative design was proposed which increased the overall thickness of the slab, sub-base preparation and corresponding excavation, and required steel reinforcement; of most significance, this increased cost.

Maybe there’s a better way?

Enter Mr. Brett Cooper, owner and VP of Construction Perfected, Inc. (CPI). He heard about the impressive results EdenCreteTM had achieved with Augusta Ready Mix at the GDOT trial (see Stories of Strength – Georgia Highways). He reached out to Augusta Ready Mix for a consultation about the project. After careful study, the team ascertained that CPI could achieve the durability, quality and longevity the railcar facility desired by using the EdenCrete™ carbon concrete

additive—without much else.

The Test

Using the same formulation as the GDOT trial (minus the accelerator), CPI poured a 10 cubic yard slab enriched with EdenCrete™, and a second “control” slab without EdenCrete™. Six months later, the EdenCrete™ slab looked great and had not cracked. However, the “control” slab showed major cracking.

The Results

The new results with EdenCrete™ were so promising that CPI and the facility’s owner decided to move forward with the EdenCrete™ solution. The EdenCrete™ solution is expected to at least double the concrete life, yet require much less concrete, no steel reinforcing and greatly reduce excavation time. Consequently, the budgeted repair costs, with EdenCrete™, are 20% less than the earlier proposed ultra-high strength concrete design.

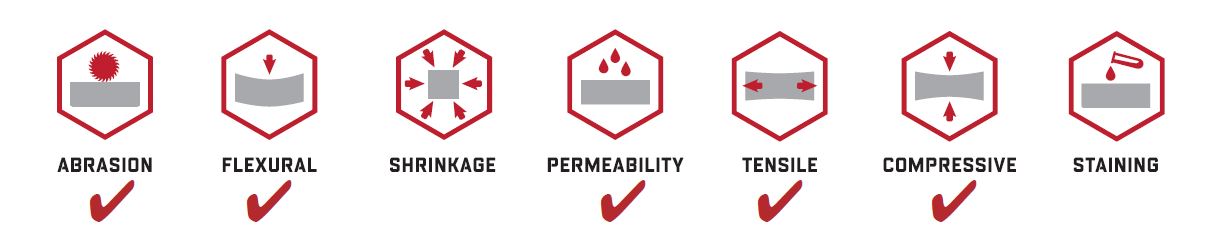

Areas of significant improvement for this application

EdenCrete™ enhances concrete in all seven areas, but was specifically selected for abrasion, flexural, permeability, tensile, and compressive strength for this project.

EdenCrete™ test slab (1) shows no signs of cracking or wear, while the control slab (2) without EdenCrete™ is showing cracking already. 3. Example of heavy Railcar axles and other parts that are constantly impacting the concrete slabs.

“We couldn’t be more pleased with this. It’s not every day you get to reduce the cost of a project for a client almost 50% and still deliver to them the quality and reassurance they’re asking for in the service-life of the concrete. EdenCrete™ is a great concrete additive and we are excited to have discovered its existence. This technology could be a game changer for the concrete industry,” said Brett Cooper, (Owner and V.P. of CPI).